We speak with Damian Thorpe, Advanced Milling Instrumentation Manager, about the key factors every site needs to consider when choosing and using instrumentation to optimise milling performance.

Key Facts

- Using the right instrumentation effectively will transform milling performance, not just offer incremental improvements.

- Choosing instruments that can withstand harsh operating environments means they will continue to provide reliable and accurate data.

- Investing in modular instrumentation systems enables operations to scale up as they grow.

To find out what really matters when selecting instruments for milling optimisation, we spoke with Damian Thorpe, Molycop’s Advanced Milling Instrumentation Manager, based in Perth. Here he draws upon his extensive experience across a range of mining operations to provide five key considerations every site operator should keep in mind:

To find out what really matters when selecting instruments for milling optimisation, we spoke with Damian Thorpe, Molycop’s Advanced Milling Instrumentation Manager, based in Perth. Here he draws upon his extensive experience across a range of mining operations to provide five key considerations every site operator should keep in mind:

1. Ore characteristics and variability

No two ores are the same – even within the same deposit, variability can significantly impact performance. Damian highlights the importance of understanding ore hardness, density and grindability before selecting instrumentation.For example, softer ores may benefit from real-time particle size monitoring, while harder materials demand energy-based solutions. Molycop tailors its instrumentation packages to suit specific ore types and operational needs, ensuring operators get actionable data that adds real value.

2. Reliability in harsh environments

2. Reliability in harsh environments

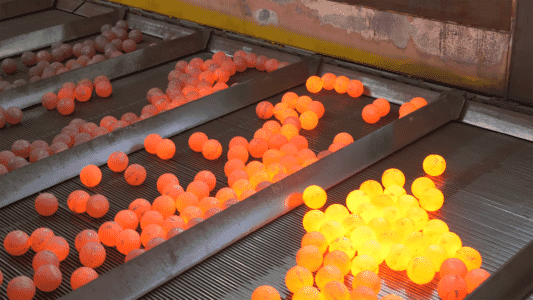

Mining environments are notoriously challenging: heat, dust, slurry and vibration can compromise instrument reliability and integrity. Damian emphasises that several of Molycop's instruments are specifically engineered to perform reliably in these harsh conditions. Data integrity is the aim – an unreliable data source cannot be successfully integrated into process control. With self-cleaning lenses, industrial-grade enclosures and materials, and AI-powered image processing, Molycop instruments consistently deliver accurate, high-quality data, even in the most demanding areas of the plant.

3. Data integration with existing systems

3. Data integration with existing systems

Damian says: "An instrument is only useful if it speaks the same language as your control system.”That’s why Molycop focuses on seamless integration with existing infrastructure – from SCADA, PLC and DCS systems to Molycop platforms like Molycop Data Platform and MillROC. Molycop instruments don’t just collect data, they deliver it in real time where it matters most: into the hands of operators, engineers and decision-makers.

4. Scalability and modularity

4. Scalability and modularity

Needs evolve. A site's instrumentation strategy should too.According to Damian, one of the most common mistakes is investing in closed systems that can’t grow with a plant's growth. Molycop’s modular instrumentation allows sites to start small – perhaps monitoring just the cyclone overflow – and scale up to cover the entire circuit, from feed to flotation.

5. Support and maintenance

5. Support and maintenance

Reliable instrumentation isn’t just about installation – it’s about long-term performance.Damian underlines the importance of ongoing support, particularly for remote or high-throughput sites. Molycop goes beyond supplying equipment, offering remote diagnostics and onsite training, plus local technical teams who understand plants’ unique processes. This ongoing partnership ensures instruments remain accurate, calibrated and aligned with customers’ optimisation goals.

Final thoughts

Final thoughts

Instrumentation is a strategic investment and getting it right requires more than just good technology. By factoring in ore variability, system integration, environmental challenges, growth potential and long-term support, operations can unlock new levels of efficiency and throughput.Molycop is proud to support its customers on their journey, with instrumentation solutions designed by experts like Damian Thorpe and his team, and a commitment to helping partners achieve operational excellence.