Rail Wheels

Molycop manufactures the Comsteel range of forged and rolled rail wheels to International Standards for all classes of rolling stock.

Read More

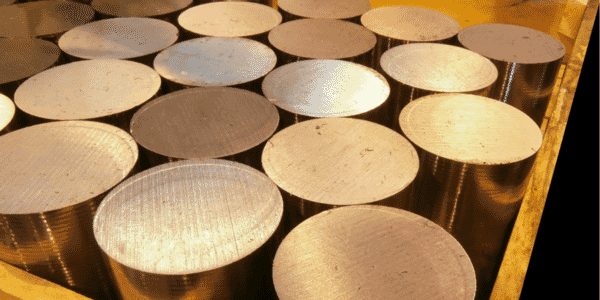

Molycop produces precisely engineered and durable anode pins for use as cathodes and in anode stub applications in several Australian and New Zealand smelters.

Make An Enquiry

Molycop manufactures the Comsteel range of forged and rolled rail wheels to International Standards for all classes of rolling stock.

Read More

Molycop is a trusted supplier of high-performance engineered products for the Australian rail and manufacturing industries.

Read More

Molycop is continuing to develop standards for its manufacturing of wheels with a focus on sustainable practices.

Read More

Molycop is well and truly an Australian institution, with the company’s origins harking back to 1917, when it began as the Commonwealth Steel Company (Comsteel).

Read More

High hardness micro alloy wheels for railway rolling stock.

Read More

Molycop Australia, established in 1919, leads with advanced manufacturing plants in Newcastle, New South Wales, and Perth, Western Australia. Perth is also the home to Molycop's global process optimisation and digital technology centre.

Read More

At Molycop, we see innovation as a way to find solutions to some of the mining industry’s greatest challenges. We aim to improve on today so we can deliver better for tomorrow.

Read MoreWe use cookies, including third party cookies, for operational purposes, statistical analyses, to personalize your experience, provide you with targeted content tailored to your interests and to analyze the performance of our advertising campaigns.

To find out more about the types of cookies, as well as who sends them on our website, please visit our dedicated guide to managing cookies.