Molycop OreVia, a new suite of AI-based technologies, brings real-time clarity to mineral processing. By combining advanced computer vision with machine learning, OreVia promotes efficiency, consistency and profitability across every stage of the circuit.

Key Facts

- Molycop’s new OreVia suite uses computer vision and machine learning to deliver real-time process characterisation and control.

- OreVia works across the entire processing circuit and integrates with Molycop’s VIP Platform for local or cloud-based monitoring.

- OreVia has a number of critical benefits: it reduces variability, maximises recovery, reduces downtime and improves decision-making.

Real-time measurements, continuous improvement

At its core, OreVia uses high-resolution imaging and machine learning to capture and interpret data across the entire mineral processing circuit. The system can be installed at key points – from primary and secondary crusher discharges to mill feeds, flotation tanks and directly into a slurry pipe – to provide continuous, real-time measurements that evolve and improve over time.OreVia gives mining operations the power to see what’s happening inside their circuit, says Damian Thorpe, Manager, Advanced Milling Instrumentation at Molycop:

Operators are no longer working in the dark. They can make dynamic adjustments, reduce downtime and continuously optimise without expensive interruptions.

Unlike traditional systems that rely on delayed or static measurements, OreVia applies computer vision to detect process variations as they happen, alerting operators early and helping them act before small inconsistencies escalate into costly inefficiencies. Seamlessly integrating with both plant control systems and the Molycop VIP Platform, OreVia supports local and cloud-based monitoring, with intuitive interfaces for on-site operators and enterprise-level reporting across multiple operations.

OreVia uses real-time particle size and shape analysis to improve recovery.

A modular approach to reducing process variability

Process variability is one of the biggest challenges in mineral processing, affecting everything from product quality to recovery rates. Molycop’s OreVia suite tackles this head-on by providing real-time insights that reduce fluctuations, stabilise operations and improve control. The results are tangible: lower reagent and energy use, improved throughput and recovery, and stronger margins through better decision-making.A key benefit of OreVia is its adaptability to every operation. Its flexible, modular ecosystem is designed to grow with each site’s changing needs. OreVia’s algorithms evolve alongside new applications, ensuring long-term adaptability as both technology and operations advance.

The suite spans three key dimensions, each addressing a critical stage of the mineral processing circuit:

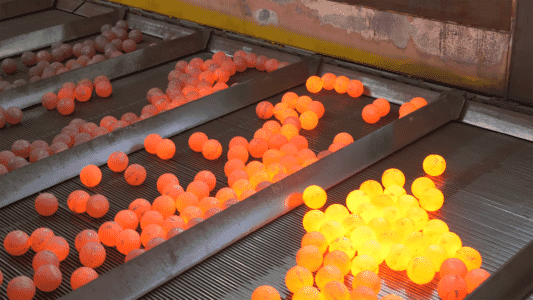

- OreVia Rock – AI-powered coarse ore detection to stabilise mill feed and enhance circuit performance.

- OreVia Slurry – Real-time particle size and shape analysis for better grinding control.

- OreVia Froth – Continuous froth monitoring to optimise flotation and extraction efficiency.

A connected vision for the future

With its modular, adaptable and extendable design, OreVia represents the next generation of intelligent process optimisation, enabling operators to see, understand and optimise their processes with unprecedented clarity.“With OreView we connect every stage of the ore journey in a way that delivers measurable results,” Damian says. “It’s process characterisation made smarter.”