Molycop presented its latest advance in particle size analysis technology at MetFest Perth, proving that innovation is driving smarter, more efficient methods of mineral processing.

Key Facts

- Molycop unveiled its next-generation slurry particle size analysis technology, delivering accurate, real-time insights without disrupting plant operations.

- The system’s AI-driven image analysis provides a precise Particle Size Distribution (PSD), helping operators optimise performance and respond faster to process changes.

- The technology can be tailored to specific applications, whether in the laboratory or in large-scale plant environments.

With this year’s theme being ‘Metallurgy: A Crucial Strength Throughout the Value Chain – Share, Learn, Collaborate and Actions’, the event celebrated the essential role metallurgy plays across every stage of the mining value chain – from resource definition to processing and optimisation.

The next generation of particle size analysis

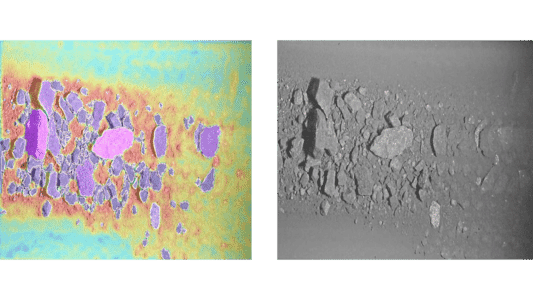

Damian Thorpe, Manager: Advanced Milling Instrumentation, presented one of Molycop’s latest innovations in particle size analysis for slurry applications. The technology has been designed to detect fine particle size and fragmentation in pipes, adapting to process variability while providing real-time, high-resolution fines analysis and particle size measurements – all without the need for subsampling. An endoscope captures images that allow AI-driven analysis of particle size and shape.

An endoscope captures images that allow AI-driven analysis of particle size and shape.Using a high-resolution endoscope installed directly into the slurry pipe, the system captures detailed images that allow AI-driven analysis of particle size and shape. This delivers a precise Particle Size Distribution (PSD) that quantifies ore fragmentation, providing critical data to support process optimisation. The technology also offers remote monitoring and playback features, and integrates seamlessly with existing plant control systems, making it an invaluable tool for metallurgical and process teams.

Damian explains the technology to MetFest Perth attendees.

Damian says the technology delivers accurate, real-time insights into particle size without interrupting operations:It gives plant operators the visibility they need to make informed decisions, improve performance and respond quickly to changes in the circuit.

The technology can be tailored to specific applications, ensuring flexibility for both laboratory and plant-scale environments.

Connecting with peers

Joining Damian at the event were Adrian Paine, Manager: Gold Processing, Matt Brooks, Sales Manager, and Omar Sultan, Process Engineer, all of whom contributed to a dynamic day of discussion, client engagement and technical collaboration.“MetFest is always a great opportunity to connect with our peers and see the direction the industry is heading,” said Adrian. “Events like this help keep innovation at the forefront – both in technology and in how we collaborate.”

Matt added: “It’s fantastic to meet clients face-to-face, share updates on the work we’re doing, and learn what challenges they’re tackling on site.”

The event concluded with a relaxed evening networking session, allowing participants to continue conversations and explore opportunities for future collaboration.

.png?h=300)