Embark on a compelling narrative of innovation and success as we unveil the transformative journey of Agnico Eagle Fosterville Gold Mine (Fosterville), a beacon of excellence in the Australian gold mining landscape.

Transforming Challenges into Triumph: Fosterville Gold Mine's Milling Optimization Journey

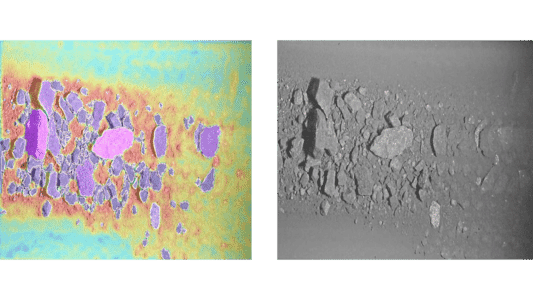

Embark on a compelling narrative of innovation and success as we unveil the transformative journey of Agnico Eagle Fosterville Gold Mine (Fosterville), a beacon of excellence in the Australian gold mining landscape. Operating a complex gold plant with a circuit that includes a SAG mill, closed-loop cyclone classification, flotation, bacterial oxidation, and leaching circuits, Fosterville faced a unique set of challenges that demanded inventive solutions.

The absence of surge capacity between the grinding and flotation circuit, coupled with restrictions on crushing operations due to noise constraints, presented formidable obstacles. Yet, Fosterville rose to the occasion, turning challenges into opportunities with the implementation of a novel control solution that leveraged advanced instrumentation.

The primary objectives of this pioneering control solution were twofold: to elevate grinding efficiency and ensure a consistent feed to the flotation circuit. Unlike many other grinding operations, Fosterville's focus wasn't solely on maximizing throughput; instead, the emphasis was on mine constraints. The feed density to the flotation circuit emerged as a critical variable, with low densities potentially impacting recoveries. With no surge capacity between the grinding and flotation circuits, stabilizing the cyclone overflow density to the flotation circuit became integral, stabilizing not just the grinding circuit but also ensuring a consistent feed of the required density to the flotation circuit.

Control strategies encompassed cutting-edge approaches, including the utilization of cameras for feed control, optimizing flotation feed density, and stabilizing the discharge circuit. The outcome? An impressive trifecta of positive results: improved circuit stability, increased recoveries, and a notable 11% reduction in specific energy. Beyond operational efficiency, these achievements hold the promise of potentially reducing CO2 emissions by 806 tonnes/year, underlining Fosterville's commitment to sustainability.

This success story at Fosterville Gold Mine stands as a testament to the power of collaboration, innovation, and a steadfast commitment to overcoming operational challenges. Dive into the intricacies of this triumph in milling optimization by exploring the full case study on our website.

Click here to read the case study: Molycop Case Studies | Molycop

Witness firsthand the transformative potential that defines Molycop's dedication to excellence.

Molycop- Progress Together

.png?h=300)