Molycop has conducted the second of its Masterclass series events in Indonesia, enabling its customers to build capability, solve operational challenges and improve plant outcomes.

Key Facts

- The Molycop Masterclass series provides attendees with the practical skills and expert insights they need to transform plant performance.

- The agenda featured theoretical instruction, case studies, hands-on learning and open dialogue between participants and presenters.

- Molycop is a partner in its customers’ performance, with Molycop experts sharing their knowledge and working together with customers to solve their challenges.

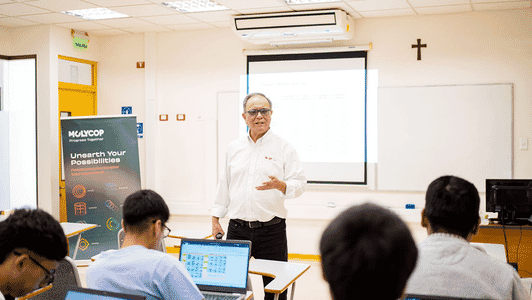

Levi Guzman presents on Day 1 of the Masterclass.

Levi Guzman presents on Day 1 of the Masterclass.Held over two days at The Westin Jakarta, the event brought together metallurgists, engineers and plant professionals from across the region. With a program focused on SAG milling, flotation and process optimisation, the Masterclass provided attendees with practical tools, expert insights and a direct line to Molycop’s global technical specialists.

“This Masterclass has become a fixture on the calendar for many of our customers in Indonesia,” said Salyo Dikdoyo, Commercial Development Manager, Molycop Indonesia. “It reflects a clear appetite for knowledge sharing and a commitment to continuous improvement in plant performance.”

Expert presenters

The 2025 Indonesia Masterclass featured in-depth sessions led by:- Levi Guzman, Global Lead – Technical Applications: Levi delivered two technical deep-dives on SAG and ball mill optimisation, drawing from global site experience and operational benchmarks.

- Dr Hamid Pourasiabi: Hamid presented the Ball Mill Abrasion Test (BMAT), demonstrating its value as a practical tool for understanding media wear and performance.

- Dr Yufan Mu: Yufan introduced the Mill Family Model and explored how pulp chemistry influences grinding circuit efficiency.

- Vishal Deeplaul: Vishal shared the latest developments in mill optimisation using advanced digital modelling tools, including Discrete Element Modelling (DEM).

A comprehensive agenda

Over both days, the agenda featured a balance of theoretical instruction, case studies, hands-on learning and open dialogue between participants and presenters. Attendees left the event with practical strategies they can apply directly to site challenges.Zai Husnaa, Molycop Business Development Manager, said:

What sets the Molycop Masterclass apart is its practical orientation. Participants walk away with knowledge they can apply at their site the very next day.

More than just a training event, the Masterclass reflects Molycop’s ongoing commitment to investing in the Southeast Asian region. By dedicating time, resources and expertise, Molycop aims to support customers in building capability, solving operational challenges and improving plant outcomes.

According to Levi Guzman:

We believe in being more than just a supplier – we are partners in performance. That means turning up, sharing our knowledge and listening carefully to the challenges our customers face – and then working together to solve them.

Alex Zheng, Project Manager (Asia), presents on Day 2.

Thanks from Molycop

Molycop extends its sincere thanks to all who attended and contributed to the success of this year’s event, especially the delegates who made time to participate and the presenters who shared their expertise. As part of the growing Molycop Masterclass Series, Molycop can confirm that the tour will soon return to Australia, with two new events planned in the coming months.

As part of the growing Molycop Masterclass Series, Molycop can confirm that the tour will soon return to Australia, with two new events planned in the coming months.

Molycop – Progress Together

Molycop – Progress Together