Molycop Senior CAE Simulation Engineer Boris Sullacahuaman helps customers unlock the full potential of DEM, a powerful simulation tool that turns mill data into actionable insights and provides measurable results. We spoke to him in the lead up to his Insights webinar.

Key Facts

- Optimise performance: DEM simulations enable customers to fine-tune mill speed, reduce liner wear and cut energy consumption.

- Data-driven savings: Real-world case studies show DEM analysis can deliver energy reductions of up to 14%.

- Learn from an expert: Join Boris’ Insights webinar to gain practical tools and find out about real examples of how DEM supports smarter, more efficient mill operation.

Ahead of his Molycop Insights webinar on 19 November, titled Discrete Element Method (DEM) Simulations: Unlocking Insights in Comminution and Mill Optimisation, we spoke with Boris Sullacahuaman, Senior CAE Simulation Engineer at Molycop, to understand the value of DEM and how simulation is reshaping mill optimisation.

Senior CAE Simulation Engineer Boris Sullacahuaman

Senior CAE Simulation Engineer Boris Sullacahuaman

Turn data into decisions

Boris leads Molycop’s computer-assisted engineering (CAE) team in designing, executing and validating simulation studies for customers around the world. His primary responsibility is to define the objectives of each project and identify how the analysis can address a customer’s challenge. Boris also develops new procedures for applying CAE tools, which are later validated in the field.One recent project illustrates the positive impact Boris' technical services team can have. The team demonstrated to a customer that they did not need to run at maximum mill speed from the start of their liner campaign. By optimising speed through DEM analysis, the customer reduced energy consumption while maintaining performance. The result was validated on site and delivered significant cost savings.

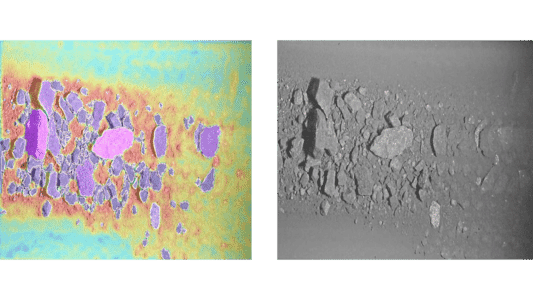

DEM simulations turn mill data into actionable insights and provide measurable results.

DEM simulations turn mill data into actionable insights and provide measurable results.

From case study to case success

Boris shares two other recent examples where use of DEM simulations translated into measurable benefits.In one case, his team simulated charge trajectories and identified that high liner impacts occurred early in a liner campaign. Adjusting ramp-up speeds reduced impacts, optimised energy use and cut energy consumption by 14% without sacrificing throughput.

In another case, DEM simulations revealed that operational conditions were generating direct ball impacts on grates. Coupled with finite element modelling (FEM), the analysis predicted fracture zones that were later confirmed during grate inspections. Preventive changes were made, extending component life and improving safety. (Note that these results are based on specific case studies and actual outcomes will vary depending on site conditions and operational factors.)

Looking ahead: DEM for today’s mining challenges

For Boris, the relevance of DEM today is clear. It’s a tool built for optimisation and efficiency, grounded in physics. As sustainability pressures rise, metallurgists, process engineers and grinding specialists need to do more with less – less energy, less steel, less downtime. DEM helps make that possible.

Join the webinar

Don’t miss the oppportunity to hear directly from Boris Sullacahuaman at his Insights webinar on 19 November.The session will give participants practical takeaways they can apply immediately – such as how to evaluate ball size, optimise mill speed and predict liner impacts – backed by real case studies that demonstrate the financial and operational benefits of DEM. Note that the webinar will be conducted in Spanish.

.png?h=300)