Overview

Molycop’s lab testing services offer a range of precise techniques to assess ore floatability and optimise flotation circuit performance. Through methods like batch flotation, flotation kinetics tests and locked cycle tests, Molycop provides detailed insights into ore separation, helping clients refine reagent selection and improve recovery rates at each stage of the flotation process.

Molycop lab testing is conducted to:

- assess ore floatability

- maximise mineral recovery while minimising gangue flotation

- recover particles not recovered during rougher flotation

- re-float products of rougher and scavenger flotation to maximise grade.

Mineral characterisation

Prior to Molycop lab testing, a detailed characterisation of the head mineral is carried out to assess:

- humidity

- specific gravity

- chemical analysis

- granulometric analysis

- pulp natural pH

- lime consumption.

Stages of flotation

Batch flotation, in which a 1–2kg sample of ore is floated using a standard set of operating conditions, is the standard technique used to assess ore floatability.

Batch tests are usually performed using the feed ore sample to the process, but they are increasingly being used to characterise the floatability of internal flotation circuit streams and ‘map’ how the floatability is changing around a flotation circuit and across different processes. There are two key stages of flotation:

1. Rougher: The first stage of separation and concentration whereby recovery of the desired minerals is maximised while minimising gangue flotation. The proper collector selection is critical in this respect.

Tailings from rougher and, in some cases, recycled cleaner flotation tailings are floated, often with additional collector and frother, to maximise the recovery. The objective is to recover particles (i.e. middlings) not recovered during rougher flotation.

2. Cleaners: The second stage of concentration whereby the products of rougher and scavenger flotation are re-floated to maximise grade. In most cases, the rougher and scavenger concentrate are reground before cleaner flotation. Multiple cleaning (re-cleaning) stages may be necessary to obtain a marketable concentrate. Small amounts of collector are usually added and aid recovery in the cleaning stages.

Types of testing

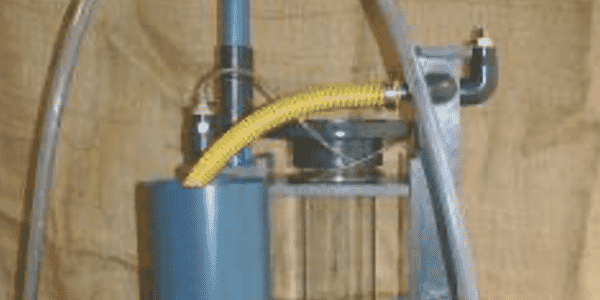

Batch Flotation Test

Molycop supports its customers to conduct metallurgical analysis of the main flotation tests on a laboratory scale.

Rougher float tests:

- Effect of the type and dose of reagents (collectors, foaming agents, dispersants, depressants, etc.)

- Effects pH, P80, percentage of solid, type of water (process, sea, osmosis)

Flotation kinetic tests:

- Determination of the kinetic constant (K) and maximum recovery (Rmax).

Cycle Float Test

Open and closed cycle flotation tests:

- evaluate the design of the flow sheet and the set of flotation reagents (collectors, frothers, dispersants, depressants, etc.)

- produce a metallurgical projection for a study sample.

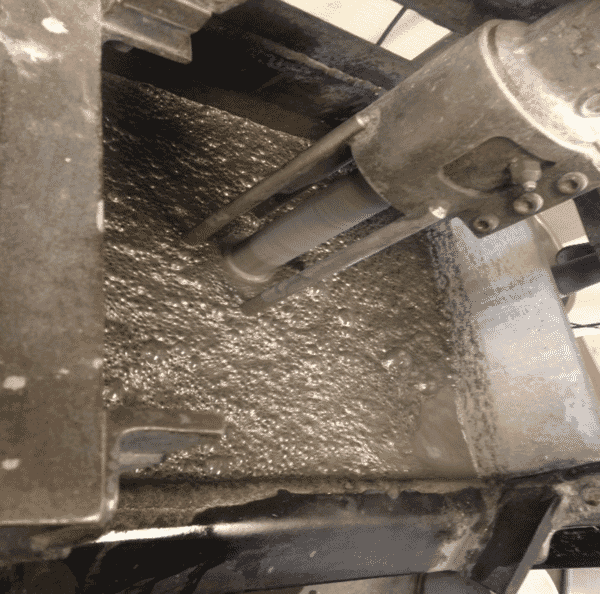

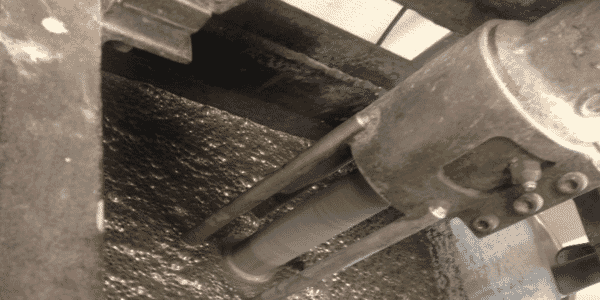

Characterisation of sparkling

The Bubble Sizer is a portable device that is used to:

- determine size and distribution of bubbles and Jg (superficial velocity of gas) in flotation cells

- determine the optimal dose of sparkling for improved foam stability and grade of concentrate.

X-Ray Fluorescence Analysis

FRX Bruker S1 TITAN Portable Pistol:

- Fast and secure analysis.

- Manufacture and calibration of own curves.

- Improved measurement accuracy.

- Improved detection limits.

Optimisation of processes through DOE and RSM

Application of design of experiments (DOE) and Response Surface Methodology (RSM) statistical techniques for the planning of test programs and analysis of results:

- Full Factorial Design (2n).

- Fractional Factorial Design (2n-1).

- Composite Central Design (CCD).

- Response Surface Methodology (RSM).

Kinetics Test

The practical flotation time required for an ore can be determined by producing incremental concentrates. Separate concentrates are removed at timed intervals until the froth is completely barren.

Using the weights and assays for each incremental concentrate, the metal distribution in each can be determined. This information is then graphically plotted as cumulative recovery versus cumulative flotation time and used for the guidance in subsequent flotation tests.

Different collector systems will often show significant differences in flotation rates, which will be apparent by comparing their individual recovery versus time curves. It is also good practice to microscopically examine the incremental concentrates to determine the relative flotation rates of the variously associated minerals and the necessity for regrinding.

Locked Cycle Test

A locked cycle test is a repetitive batch test used to simulate a continuous circuit. The basic procedure consists of a complete batch test performed in the first cycle which is then followed by similar batch tests that have ‘intermediate’ material from the previous cycle added to the appropriate location in the current cycle.

These batch tests, or cycles, are continued in this iterative manner for a number of cycles until, ideally, the steady state is reached. The final products from each cycle – i.e. final concentrate and final tailings – are filtered and thus removed from further processing. At the end of the test, all the products, final and intermediate, are dried, weighed and subjected to chemical analysis. The test is balanced and a metallurgical projection is made.

Infrared Spectroscopy

This is an absorption method widely used in both qualitative and quantitative analyses.

The infrared (IR) region of the spectrum includes electromagnetic radiation that can alter the vibrational and rotational states of covalent bonds in organic molecules. The IR spectrum of an organic compound is a unique physical property and can be used to identify unknowns by interpretation of characteristic absorbances and comparison with spectral libraries.

Infrared spectroscopy is also used in quantitative techniques because of its sensitivity and selectivity.

Molycop’s specific services of investigation and development

Comprehensive optimisation in grinding and flotation:

- Research to optimise the grinding and flotation process through the chemical study of mineral pulp (Eh, pH, Dissolved Oxygen, etc.).

- Optimisation of the flotation process.

- Research to optimise flotation process variables, such as doses and types of reagents, granulometry, lime consumption, percentage of solids, etc.

Optimisation in the flotation of altered minerals (clays, oxides, soluble copper, etc.):

- Research to optimise recovery and grade in altered minerals.

- Decreased consumption of lime in acid minerals.

- Mitigation of the effect of clays.

Control of impurities in collective and selective flotation concentrates:

- Zinc removal in copper concentrates.

- Pyrite removal in copper concentrates.

Characterisation of frothers and study of hydrodynamics of flotation cells:

- Characterisation of sparkling wines through the Molycop methodology.

- Evaluation of hydrodynamics of flotation cells to optimise the use and dosing of foaming agents.

.png?h=300)