Control

Advanced control systems deliver improved outcomes for mineral processing operations.

Read More

Molycop has unparalleled experience working with customers to establish new mineral processing operations and sustain them for the long term.

Make An Enquiry

Advanced control systems deliver improved outcomes for mineral processing operations.

Read More

Innovation and product development lie at the heart of a sustainable future for the mining sector, says Paul Shelley, Global Vice President of Innovation, Molycop.

Read More

The initial installation and set-up of MillSlicer, MillStar and MillROC at the Edikan Gold Mine in Ghana's Ashanti Gold belt was completed by April 2019. The optimisation strategy resulted in a sustainable increase in throughput of 27% in 8 months.

Read More.png?h=300)

The objective of a MillROC improvement project at a leading Australian nickel mine was to implement a new control philosophy around the grinding circuit, which allowed for stabilisation of key operating variables. The project led to significant improvement in circuit efficiency, reduction in energy requirements and increases in throughput.

Read More

Molycop has successfully implemented a range of optimisation projects at the Edikan Gold Mine, including mine-to-mill optimisation, advanced instrumentation, and real-time consulting services to deliver sustainable increased throughput of 27% in 8 months.

Read More

In partnership with Mintek, we design, commission and implement advanced control systems to deliver improved outcomes for your mineral processing operations.

Read More

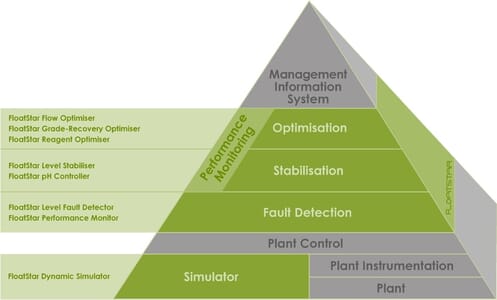

The FloatStar suite of control modules utilises advanced process control to overcome design-related limitations and maximise circuit performance during operation.

Read More

At Molycop, we see innovation as a way to find solutions to some of the mining industry’s greatest challenges. We aim to improve on today so we can deliver better for tomorrow.

Read MoreWe use cookies, including third party cookies, for operational purposes, statistical analyses, to personalize your experience, provide you with targeted content tailored to your interests and to analyze the performance of our advertising campaigns.

To find out more about the types of cookies, as well as who sends them on our website, please visit our dedicated guide to managing cookies.