Overview

OreVia detects fine particle size and fragmentation in pipes, adapts to variability in particle size, and provides real-time high-resolution fines analysis and particle size measurements, without the need to sub sample.

The technology consists of a high-resolution endoscope installed directly into a slurry pipe to retrieve particle size and shape information via image analysis. Only one endoscope is provided, and the measurement range will be determined in collaboration with the client to best suit their needs. Typical measurement ranges are:

- 1–200 µm for fine particles.

- 10–1100 µm for coarser particles.

The system works by identifying the outline of fine particles in the crusher process discharge stream using AI-powered technology. It then calculates rock size based on the best-fitting ellipse for each rock. The outcome is a Particle Size Distribution (PSD) that measures the fragmentation of the ore.

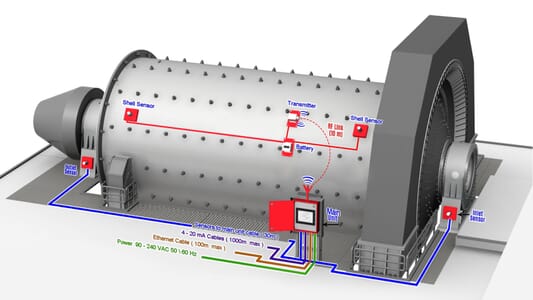

The system offers remote monitoring and playback features and integrates seamlessly with existing control systems. OreVia can easily be evaluated off-site through quick image-based demonstrations provided by Molycop using client slurry samples.

Real-time fragmentation control

Artificial Intelligence has paved the way for robust, affordable and accurate particle-size insights.

Measurements from the cyclones (either cyclone feed or cyclone overflow) are helpful in ensuring optimal operation. For most plants, the mill P80 is a typical measurement as it significantly affects the mill and overall plant operation. Control systems can use this measurement to adjust the mill operation based on the particle size of the ore discharged. This measurement can be used to understand the effects of changing ore characteristics, milling density, mill feed rate, etc. It can also be used to tune the performance of the cyclones themselves.

Data is continuously collected in real time and securely stored in a time-series database, ensuring a comprehensive record of process performance. This structured data allows for easy retrieval, trend analysis and in-depth evaluations, enabling operators to monitor changes over time, identify patterns and make informed decisions to optimise efficiency and performance.

With deep expertise in control solutions, Molycop seamlessly integrates OreVia into control systems to enhance operational efficiency. Designed for compatibility with Molycop’s advanced optimisation suite, including MillSlicer and MillStar APC, this solution ensures precise mill performance and process control.